10 Powerful Stories That Show Kindness Always Finds Its Way Back

Ok, so right after being produced, plastic water bottles aren’t the size you buy at the store. Even a gallon water bottle starts its life as a small tube. Later, it gets heated, inflated, and shaped into the bottle you know. Boy, I can relate to the heated and inflated part.

Not all potato chips are actually fried potato slices. Some companies use a mix of potato flakes, corn starch, and water to produce chips. This mix is then pressed into a dough, and chips are cut out from it with the help of shape molds. Then the chips are fried, which takes about 11 seconds. After that, all excess oil gets drained, and the chips are seasoned and packed.

There’s a legend that only two people in the world know the original recipe that gives Coca-Cola its signature taste. These people aren’t allowed to travel together so that the recipe never gets lost. Even though it’s just a popular legend, not many people are aware of all the ingredients of the world-famous drink. One of them used to be the kola nut. Hey, I used to be a Cola Nut!

You can find these nuts inside the fruit of the kola tree. Each fruit is about the size of a chestnut and has between two and five kola nuts inside. The kola fruit and nuts are packed with caffeine. Nowadays, Coca-Cola is said to no longer contain kola nut extract. It’s rumored to have been replaced with artificial flavoring. But since the drink’s recipe is such a closely guarded secret, no one knows for sure. Hey, maybe we can ask Pepsi.

These days, it’s quite simple to make a mirror. Producers take a regular sheet of glass as a base. Then they apply a reflective coating. This usually means spraying a thin layer of either silver or aluminum onto the back of this sheet of glass. This process is called silvering.

Some kinds of car wax contain carnauba wax, also called Brazil wax. That’s a vegetable wax people get from the fronds of the carnauba tree growing in Brazil. To get the wax, the leaves of this tree first get dried and then beaten. Ooh, ooh ow ow! This is how you can remove the powdery wax.

Now, pencils. First, their leads are made by mixing clay and graphite powder. This mixture is then baked. After that, pencil bodies are made. If they’re wooden, the material should be chosen carefully. It should be soft enough to sharpen but tough enough not to break. When the precut sections are delivered to the factory, they have grooves cut in them. These grooves will later accommodate the leads.

Then a special glue is added — this way, the leads will stay in place. Next, every second section is sent to a special conveyor, and the leads are placed in the grooves. Then another section is glued to the one filled with the leads. We get a large, multi-pencil sandwich. Um, sandwich — I’m getting hungry. The two parts of this “sandwich” get compressed and cut lengthways. Then they’re shaped and form separate pencils.

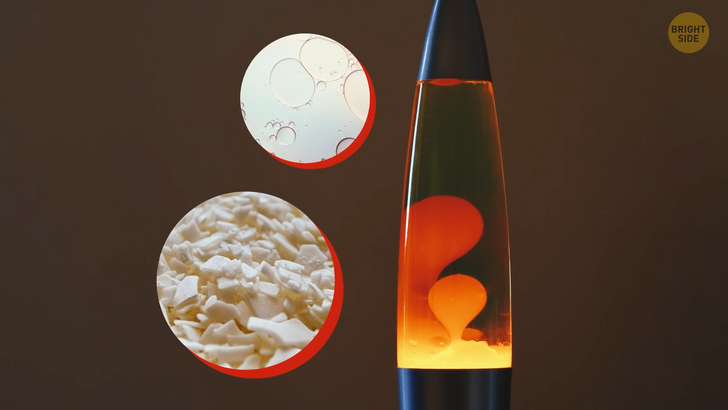

Lava lamps were invented in the middle of the 20th century. The magic happening inside is due to the right amount and type of ingredients. Two of them are oil and paraffin wax. The oil helps the wax heat up. And once it’s heated, it starts rising up slowly. Once the blob reaches the surface, it cools down and sinks back to the bottom.

Nutmeg is a strongly flavored spice used in many cuisines all over the globe. Despite its name, nutmeg isn’t a nut. It’s technically a seed native to the Spice Islands and East Indies tropical islands. Nutmeg grows on trees, and the seed itself is sealed in a shell. Once it’s ripe, the outer shell cracks open.

Chocolate comes from the cacao tree, which is native to the Amazon. These trees also grow in Central and South America and some other tropical climates in Africa and Asia. The seeds of the cacao tree are very bitter. They have to be fermented to develop the flavor you’re used to.

After this process, the beans get dried, cleaned, and roasted. The shell is removed. And crumbled bits of dried cocoa beans are ground to cocoa mass. This mass is then used in the production of all kinds of chocolatey things. Mmmm!

In the past, people used to chew different types of aromatic substances, including beeswax, tree resin, or even aromatic twigs. But modern-day chewing gum is made of a natural latex-like ingredient called chicle. It gets extracted from trees.

Modern marbles are made from glass. The first step is to melt recycled glass and previously rejected marbles that turned out to be too small or too big. About 15 hours later, the molten glass is ready for processing. A special cutter bar moves through the stream of liquid glass every half a second. It separates small pieces of glass. They’re future marbles called slugs.

The faster the cutter bar moves, the smaller the marbles are. After that, the still-hot slugs are sent through several constantly rotating metal rollers. They keep the slugs apart and also cool them. These ridged rollers also give the marbles their spherical shape. As for the marble’s final coloring, it’s determined already at the melting stage. That’s when the air passes the coloring through the glass.

You can find springs everywhere, from tools, electronics, and toys to pens and mattresses. They come in different forms, for example, torsion, wire, extension, or compression springs. When a spring is made, a steel cord is passed to a de-reeler. How thick this cord is depends on what kind of spring we need. The de-reeler unwinds the roll and sends the cord to a computer-controlled forming machine. That’s where the cord gets coiled to the needed length and cut into pieces.

To produce tomato ketchup, one of my favorites, you need tomato paste or purée, sugar or some other natural sweetener, salt, spices, vinegar, and onion powder. First, the needed volume of the tomato paste is heated while being constantly stirred. Then other ingredients are added as well. Before the ketchup is bottled, it has to get through several cooling stages. Meanwhile, bottles are already aligned and waiting to be filled with ketchup. This usually happens automatically. At the end of this process, caps and labels are added to the bottles.

Cashew nuts are rich in plant protein, healthy fats, and fiber and low in sugar. But they’re some of the most expensive nuts out there — and no wonder! The cashew tree, native to tropical regions of Brazil, produces a long stalk called a cashew apple. It resembles a small pear. Well, then why don’t they call it a Cashew Pear?

Anyway, at the end of this stalk, there’s a kidney-shaped nut. It’s protected by a double shell that contains a poisonous oily substance. It’s the main reason cashews aren’t sold in their shells like peanuts or pistachios. Cashews need to be dried and roasted first. This removes the toxins and makes the shell brittle and much easier to remove.

Nail polish as we know it today is a rather modern invention. It became popular at the beginning of the 20th century. Different companies use different kinds of chemicals and ingredients to produce nail polish. But one of these ingredients is always the same: nitrocellulose. This substance is actually liquid, but it gets mixed with plasticizers. They make nail polish more flexible and allow you to wear it longer.

The process of creating ice cream sandwiches is pretty simple. First, ice cream gets whipped. It’s done to add some air. The resulting substance is then sent to the next part of the assembly. There, two lines of wafers are already sandwiched together, and ice cream is simultaneously injected between them.

It happens so quickly that more than a hundred ice cream sandwiches can be made in a minute! Mmm, how many can I eat in a minute? There are all kinds of plastic brooms out there. But there’s one type that’s made from recycled plastic bottles. With people buying 1 million plastic bottles all over the world, it’s a cool way to reuse plastic.

Tires production is a multistep process. Tires are made from more than 15 main ingredients. Among them, there are synthetic and natural rubber, carbon black pigment, and chemical additives. Giant mixers stir these ingredients under high pressure and temperature. The final result is almost always thin rubber gum.

It gets rolled into sheets. After that, tires get assembled on a special machine. Different kinds of cloth, rubber, and metal are used for the production of a tire. Finally, the tire gets cured in a special press under more than 300˚ F of heat and high pressure. This process lasts for 12 to 15 minutes.

When they make darts, the flight shafts are produced first. 10-ft-long aluminum rods are put into a special machine. It has a few cutting tools that work from several angles at the same time. The rod turns into shafts. There are threads cut into each flight shaft so that it can be later attached to the dart barrel — that’s the part you hold and fling. On the other end, a cross-saw makes slots for the arrow flights.

At the same time, brass rods turn into the barrels into another machine. Grooves are cut into the barrels’ surface. This makes them easier to hold. And finally, they produce a dart point. It’s done with the help of a hydraulic press. It forces pointed steel into the hollow part of the barrel. And darts all there is about how they make darts.